Custom Cable Assemblies Designed for OEMs

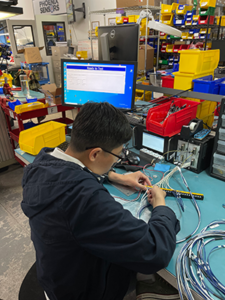

Phoenix Sensors specializes in designing and manufacturing custom cable assemblies for OEMs, ensuring the most cost-effective, reliable, and high-quality solutions. With over 30 years of engineering experience, we support low-volume prototypes, high-volume production, and everything in between. As a US-based manufacturer, we proudly build all custom cable assemblies at our Chandler, Arizona facility.

Reliable & Cost-Effective Solutions for Custom Cable Assemblies

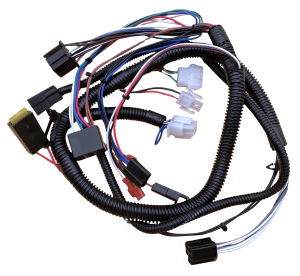

Our custom cable assemblies are engineered for high performance and durability across a range of industries. We take pride in our ISO 9001-compliant processes, which ensure consistency, precision, and RoHS compliance. With Phoenix Sensors, OEM customers can expect the following:

- Fast turnaround times, ideal for Just-in-Time (JIT) programs.

- ITAR-qualified assemblies for military and defense applications.

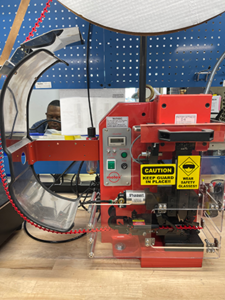

- Prototypes to high-volume production using automated processes.

- Custom solutions tailored to your unique specifications.

Delivering high-quality custom cable assemblies for industries such as:

- Military: Our assemblies meet stringent ITAR regulations and are built to perform in the harshest environments.

- Medical: Precision-engineered assemblies for medical devices that require high reliability and compliance with healthcare standards.

- Industrial: Durable custom cable assemblies designed for the most demanding industrial applications.

- Automotive: Wire harnesses and cable assemblies built for robust performance in automotive systems.

Why Choose Phoenix Sensors for your Cable Assemblies Needs?

- Made in the USA: Our cable assemblies are manufactured in-house at our Chandler, Arizona facility.

- ISO 9001 Compliant Production: Every assembly is made to IPC standards, and our process includes rigorous quality checks to ensure reliability.

- ITAR Compliance: We build ITAR-qualified assemblies to meet the needs of the defense industry.

- Prototyping to High-Volume Production: We support mid to high-volume production runs, while also accommodating low-volume projects during the prototyping and design phases.

- Customization: We tailor all cable assemblies to meet specific customer requirements, from initial prototypes to large-scale production.

Quality Control & Compliance

At Phoenix Sensors, quality is our top priority. Each custom cable assembly undergoes a rigorous quality control process to ensure that it meets your specifications and industry standards.

- Manufactured to IPC Standards: All cable assemblies are produced following IPC standards for workmanship and quality. This ensures consistent reliability across every batch.

- 100% Inspection: Each assembly is subjected to a thorough 100% visual inspection before packaging. Any assemblies requiring electronic testing will also undergo these tests to confirm functionality before delivery.

- Data File Documentation: Every assembly has a detailed Data File containing important production information, such as revision levels, schematics, bill of materials (BOM), and certificates of conformity (COC).

- ISO 9001 Compliant Processes: We adhere to ISO 9001 compliant processes throughout our organization, ensuring each custom cable assembly is built to the highest standards of quality and repeatability.

Our strict quality control measures guarantee first-time success for all our custom cable assemblies, allowing you to receive reliable, high-performance solutions every time.