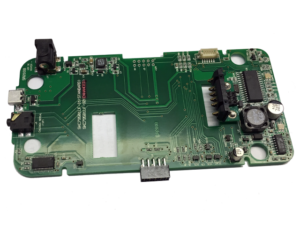

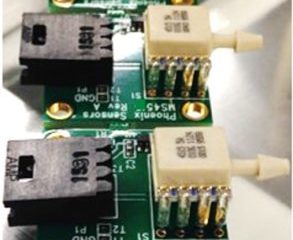

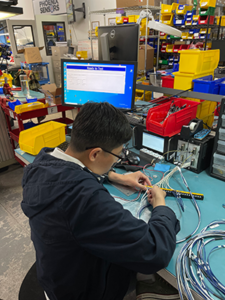

Phoenix Sensors has extensive experience in SMT (Surface Mount Technology) PCB (Printed Circuit Boards) design and assembly for quick-turn prototypes, new product introduction (NPI), and low to medium volume (10- 50k a year) production. Utilizing automated SMT equipment and Manual SMT placement enables Phoenix Sensors to assemble just about any complex printed circuit board. In partnership with Southrock Engineering, our manufacturing takes place at our facilities in Mesa, Arizona.

Our experienced technical staff can manage all aspects of turnkey solutions, from Build-to-Print, Supply Chain Management (procurement through inventory control), to JIT (Just in Time) deliveries.

Custom Printed Circuit Board Design capabilities include:

– Embedded microprocessor hardware and software

– Conversion of through-hole to SMT boards

– Conversion to lead free Compliance

– CE and Intrinsic Safety compliance

Phoenix Sensors quality control process ensures your full satisfaction. All components are inspected at each stage of production and every finished product is manufactured to IPC specifications and standards. Manufacturing is reliable, repeatable and RoHS compliant.

We are committed to first time success. Quality processes ensure that happens.

Quality Control:

Each cable or printed circuit board design has a Data File. Files are indexed by a reference number, which are customer assigned or ‘Phoenix Sensors’ designated. Each file contains the following information where available:

1. The reference number and current revision level.

2. Schematic diagram.

3. Bill of Materials, (BOM).

4. Copies of any special datasheets or parts descriptions.

5. A copy of the original quotation to the customer.

6. A form detailing the quantities and dates when the cable was previously made, and the customer PO # and the price charged.

7. Copies of the Certificate of Conformity issued with previously produced items.

8. Copies of any) Defective Material Reports (DMRs) or customer complaints, together with details of their resolution.

9. Data from previous revisions will be held in the Data file, but clearly marked as having been revised.

ISO 9001 Compliant Production:

Component parts along with Certificates of Conformity (COCs) and appropriate information from the Data File is issued to the production floor. The correct parts are confirmed and the appropriate data is entered onto the COC before production is started. We are committed to ISO9001 compliance throughout the organization.

Printed circuit boards are manufactured according to IPC standards. Any special procedures or processes required are documented and placed in the Data File. Each operator is trained to ensure that items are assembled to the required production standards.

Quality Inspection:

All items are subject to 100% visual inspection after completion. Satisfactory passing by the inspector will be noted on the COC.

When required , assemblies are tested electronically before packaging. Satisfactory passing of these tests will be noted by the tester on the COC.

On Time Delivery (OTD):

Printed Circuit Boards are delivered to the customer along with a copy of the COC.

Starting from the prototype stage, we can make a few cable assemblies or custom Printed Circuit Boards to start and accommodate your high-volumeapplications with our semi-automated processes. Phoenix Sensors serves many different industries:

- Military

- Industrial

- Medical

- Automotive

- Consumer